New materials Field

- HOME

- Business Information

- R&D Department

- New materials Field

- Thin-Film Coated Powder :

TFCP, each particle of which is coated

with layers of Nano-scale thin-film. - Speciality paper which contains

inorganic fine particle

Thin-Film Coated Powder : TFCP, each particle of which is coated with layers of Nano-scale thin-film.

TFCP exhibits various properties and possibilities.

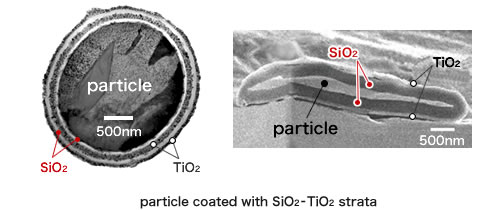

TFCP synthesis technology provides surface of each particle of a variety of shapes and materials with a smooth and precision-controlled nano-film.

Features

TFCP exhibits excellent optical properties, anti-oxidation properties, acid resistance, heat resistance, electric resistance and so on.

Optical effects

TFCP possesses a smooth and precision-controlled nano-film, so it exhibits excellent optical properties.

When coated with light interference film (dielectric film), brilliant interference color is generated even when the base material particle is opaque or the film is thin. Interference colors are shown in spherical form for spherical powder particles and in a plate form for plate-like powder particles.

When coated with a light reflecting film (metallic film), high light reflection is exhibited even if the film is thin. When dielectric film is formed on fluorescent particles as an insulating layer, luminescence intensity is improved.

Anti-oxidation properties

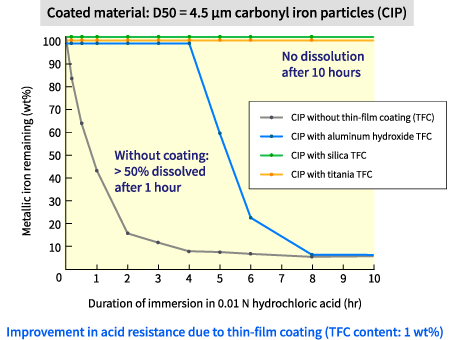

TFCP with its smooth film controlled down to the nanometer level exhibits excellent acid resistance, anti-oxidation properties and heat resistance.

When particles that are easily dissolved or oxidized with acid or heat, or those that undergo phase change accompanied by swelling are coated with silica or other nano-films, excellent acid resistance, anti-oxidation properties and heat resistance are exhibited. These effects are achieved for the first time with this smooth and minutely structured film.

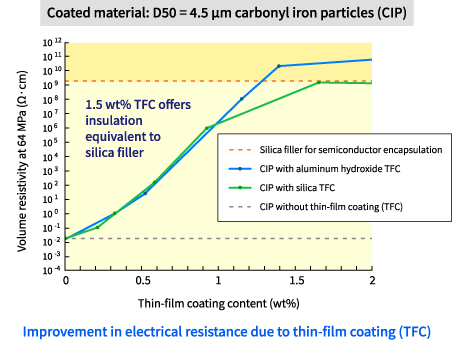

Electric resistance

TFCP each particle of which is covered with a smooth and precision-controlled nano-film exhibits excellent electric resistance.

Principles

Principles of TFCP film formation

In TFCP, the nano-film is formed through a solution reaction. It is a desirable formation method for powdery base materials. Through a solution reaction, it is possible to generate a film precipitation that can coat the surface of particulate base material evenly, thanks to the surface energy of the base material particles in the solution.

Moreover, a precision nano-film can be formed by promoting the reaction while retaining the dispersion state of base material particles in the solution.

Thin-Film Coated Powder : TFCP

Each Particle has a smooth and precisely controlled nano-film.

TFCP preparation technology provides a smooth and precision-controlled nano-film on each particle of the base material particles.

Features

TFCP possesses a smooth and precisely controlled nano-film, so it exhibits excellent optical properties. TFCP with its smooth film controlled down to the nanometer level exhibits excellent acid resistance, antioxidation properties, heat resistance, and so on.

TFCP Silica coating

TFCP exhibits excellent electric resistance.

TFCP Titania coating

TFCP possesses a smooth and precision-controlled nano-film.

| Applications |

|

|---|

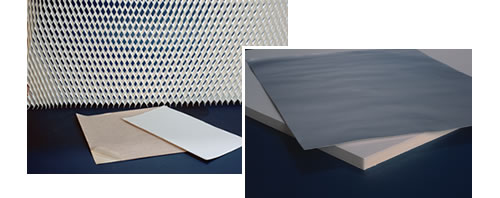

Speciality paper which contains inorganic fine particle

This technology gives new materials made of paper with characteristic of powder.

We used to conduct research and development on specialty paper and have established a technology that allows a large amount of fine particles to be incorporated into the paper.

This technology enables us to offer specialty paper that combines the "features of the paper" and the "features of the fine particles". Using this technology, we have developed and commercialized aluminum hydroxide paper with fire-resistant characteristic and calcium carbonate paper with minimal dimensional changes due to humidity.

Features

- We can make the paper, which contains powder (50wt% or more).

- We propose new speciality paper, which have "Feature of paper" and "Feature of the fine particle".

Structure

The Pulp web that mixed uniformly dispersed fine particle in a large amount.

Principles

Mechanism of nonflammable paper (Aluminum hydroxide paper)

Aluminum hydroxide paper is nonflammable because it uses the dehydration reaction of Aluminum hydroxide when temperature rises.

| Applications |

|

|---|

Speciality Paper

Speciality paper that mixed a large amount of fine particles.

Features

- Aluminum Hydroxide Paper : Aluminum hydroxide paper is incombustible paper having the self-fire extinguishing characteristics, which caused by the dehydration reaction of the aluminum hydroxide.

- Calcium carbonate paper adheres with cement and plasterboard well; dimensional stability (the expansion and contraction with humidity change) is superior.

- Crislite Paper : Crislite paper is speciality paper that mixed the porous powder. This paper has the performance that adsorbs the smell etc.

| Applications |

|

|---|